ExperimentalRaumfahrt-

InteressenGemeinschaft e.V.

Eine Initiative an der Technischen Universität Braunschweig

Unsere Arbeitsgruppen

Experimentalraketen

Die AG Experimentalraketen befasst sich mit der Entwicklung und Umsetzung von Projekten rund um den Betrieb von experimentellen Raketen.

Themen:

- Struktur (Maschinenbau, Raumfahrttechnik)

- Antriebe (Maschinenbau, Raumfahrttechnik)

- Avionik (Elektrotechnik, Informatik, Informations-Systemtechnik)

- Payload (Raumfahrttechnik, Physik, Biologie, …)

Höhenforschung

Die AG Höhenforschung befasst sich mit sämtlichen Projekten rund um Forschung in der Atmosphäre, im Orbit und auf anderen Planeten.

Themen:

- Struktur (Maschinenbau, Raumfahrttechnik)

- Robotik (Robotik, Maschinenbau, Informatik, Informations-Systemtechnik)

- Satellitentechnik (Raumfahrttechnik)

- Experimentdesign (Physik, Biologie, …)

Presse und Öffentlichkeitsarbeit

Die AG Presse und Öffentlichkeitsarbeit kommuniziert die Vorhaben und Erfolge der ERIG mit der Öffentlichkeit.

Sie erfüllt zudem unseren Bildungsauftrag, indem sie an der Organisation von Workshops beteiligt ist.

Themen:

- Social Media Management

- Verwaltung

- Finanzen und Sponsorings

- Eventplanung

Unsere Projekte

SG Rover

Projekt KERBEROS

KERBEROS ist unser aktueller Mars-Rover-Demonstrator. Mit ihm treten wir auf der jährlich stattfindenden European Rover Challenge an, in der wir uns in verschiedenen Disziplinen mit Teams aus aller Welt messen.

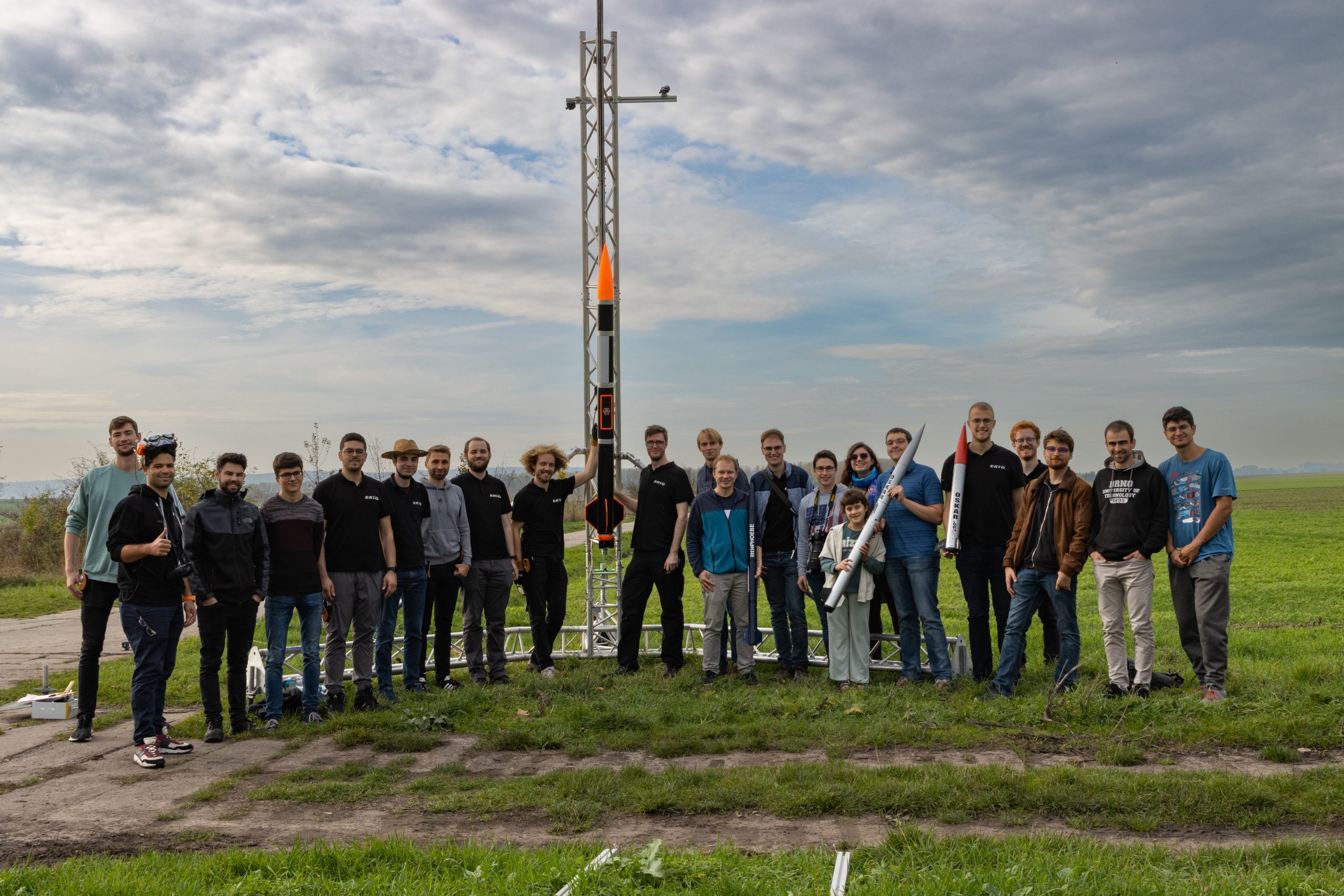

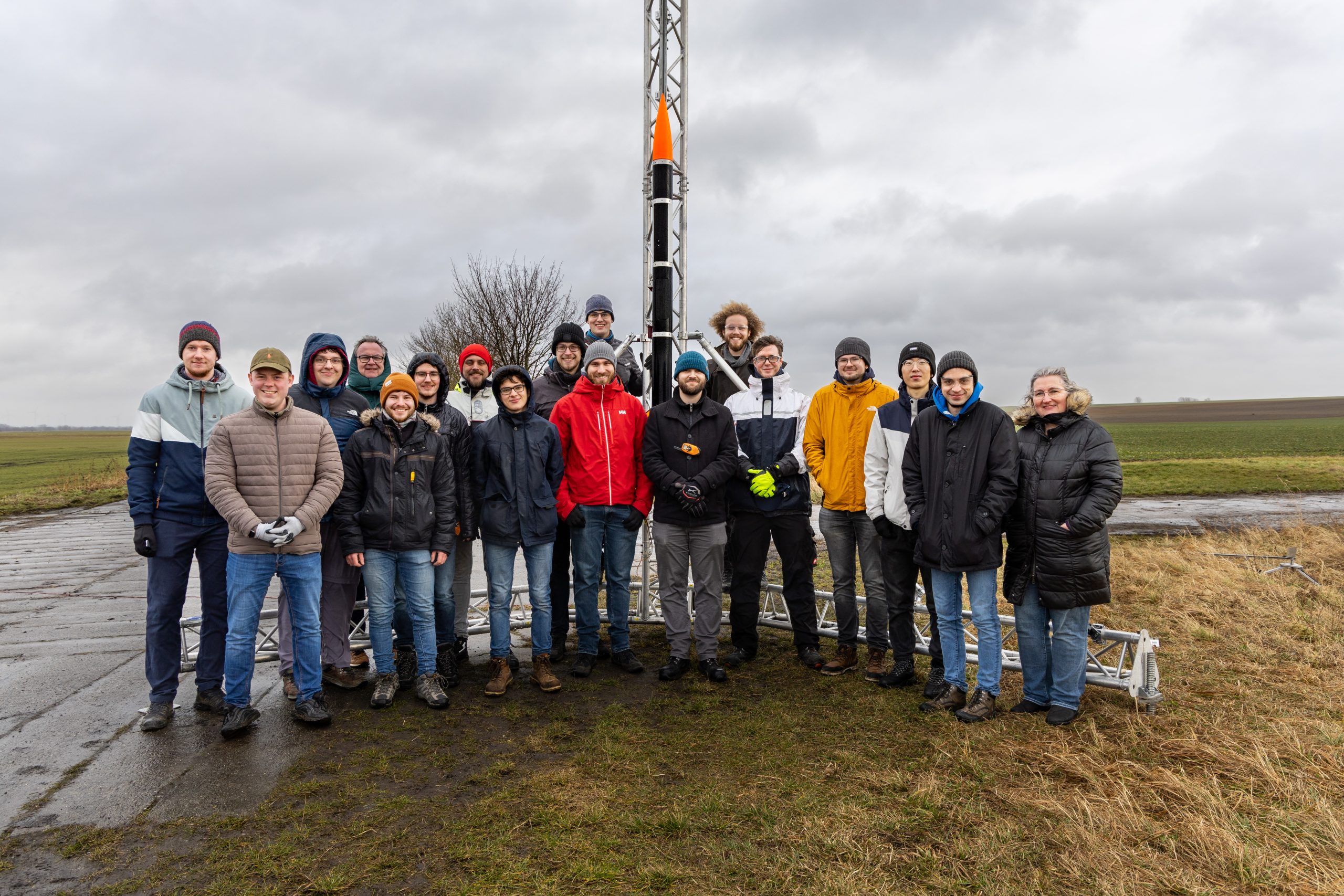

AG Experimentalraketen

Projekt UNITY

Im Projekt UNITY (Universal Iterative Hybrid Rocket) entwickeln wir die Hybridrakete Hyperion sowie die Feststoffrakete Phoebe mit einer austauschbaren Payload und einem einstufigen Fallschirmsystem.

SG Antriebe

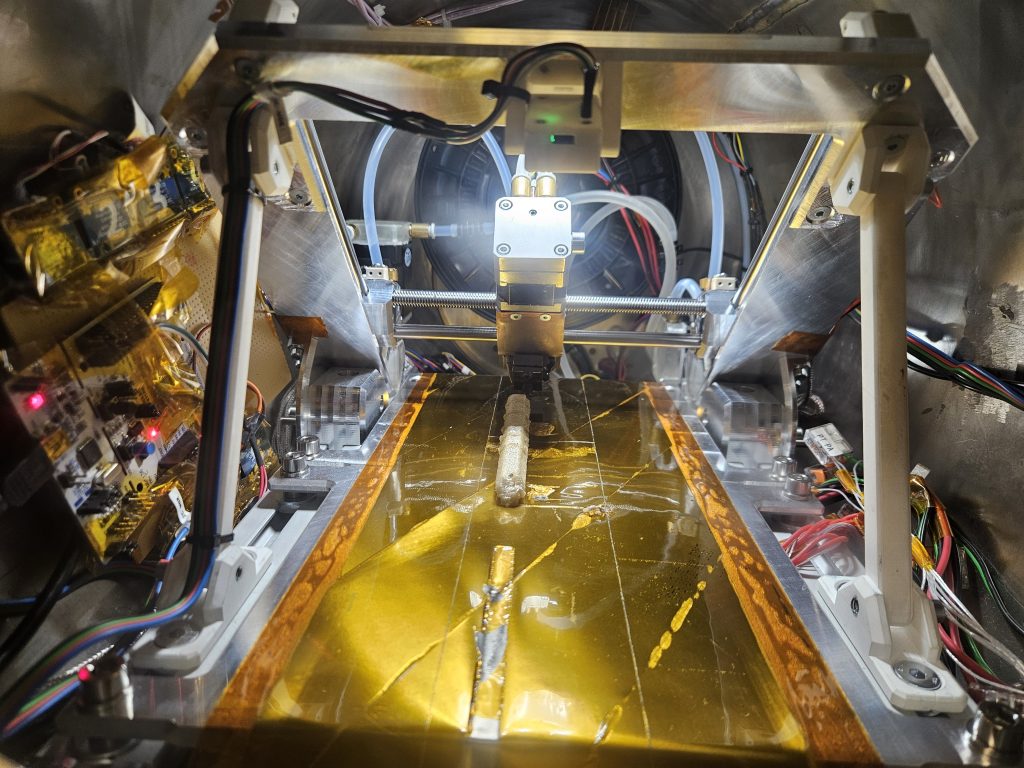

Projekt HYDRA

Im Projekt HYDRA (HybridDemonstrations-RaketenAntrieb) entwickeln wir seit 2001 eine Reihe an Hybridtriebwerken für den Flug auf unseren Raketen und für wissenschaftliche und technische Forschung.

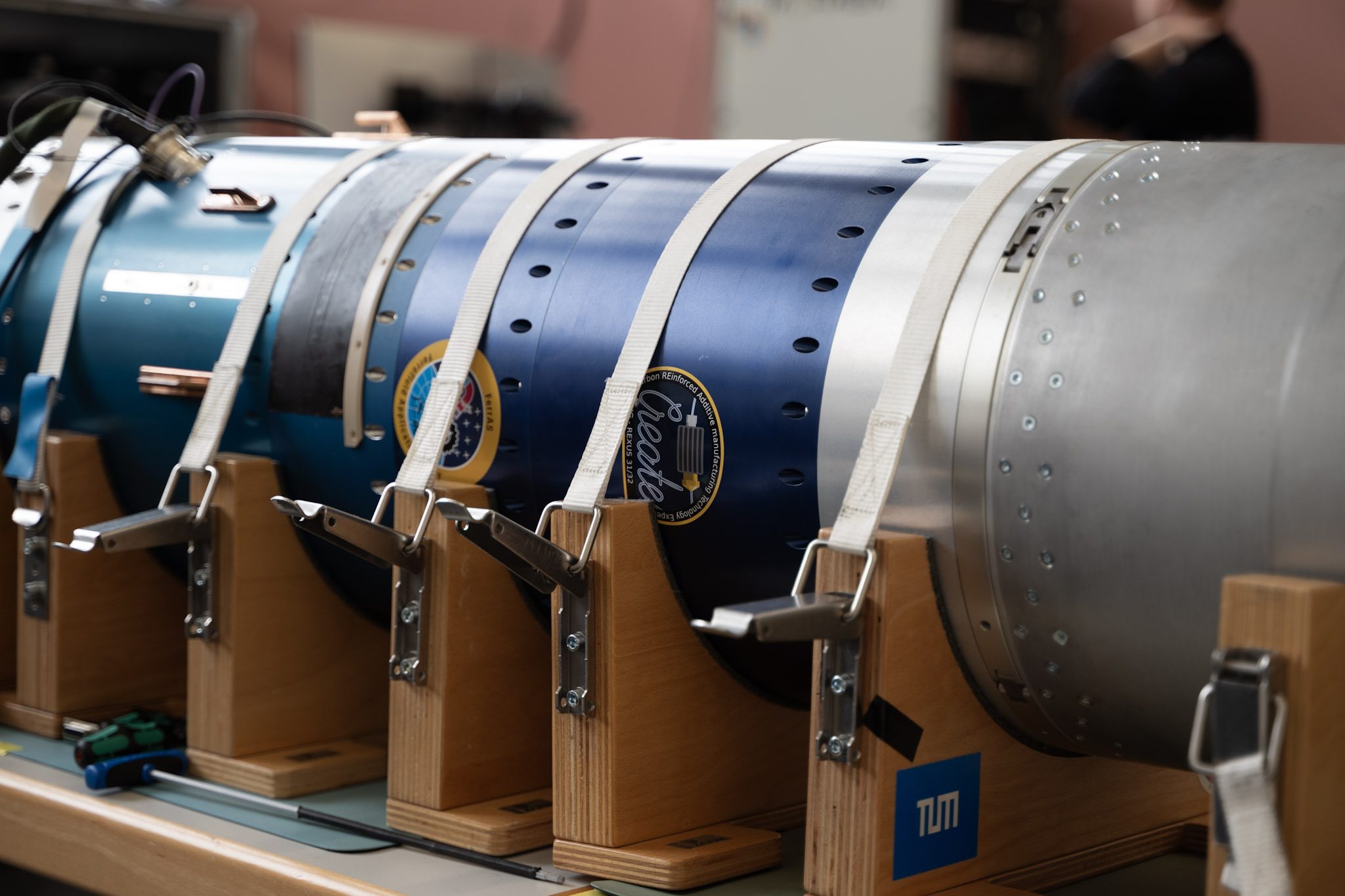

SG Höhenforschung im erdnahen Raum

Projekt MARTINI

Ziel unseres REXUS-Projekts MARTINI (Material Analysis of Resin Testing in Null-Gravity Interactions) ist die Untersuchung des Einflusses der Gravitationskraft auf den Mischprozess von Resinen.

SG Kleinsatelliten

Projekt iLOOP

Im Forschungsprojekt iLOOP (infinite Length On-Orbit Printing) entwickeln wir einen Demonstrator für eine Kleinsatelliten-Nutzlast. Ziel ist die additive Fertigung von langen Strukturen aus dem Hochleistungsthermoplast PEEK im Erdorbit.

Mitmachen

Interesse? Dann komm vorbei!

Du hast Lust, mit uns an spannenden Projekten aus der Raumfahrt zu arbeiten und dich dabei fachlich und persönlich weiter zu entwickeln? Dann tritt mit uns in Kontakt! Egal, ob du Vorkenntnisse hast oder nicht.

Jeden Dienstag um 18 Uhr ist findet unser vereinsweites Arbeitstreffen statt. Wenn du hereinschnuppern möchtest ist das der perfekte Zeitpunkt, unsere Mitglieder und Projekte kennenzulernen!

Anfahrt

So erreichst du uns!

Unsere Räumlichkeiten befinden sich am Forschungsflughafen Braunschweig im Keller des Instituts für Raumfahrtsysteme der TU Braunschweig in der Hermann-Blenk-Straße 23. Mit dem Bus erreichst du uns mit den Linien 413 und 436 (Haltestelle Luftfahrtbundesamt oder Flugunfalluntersuchungsstelle).